Pipe Adapters– Technical Details

The pipe fitting has been with us since hydraulics first appeared on the scene. And it is still with us today on applications all over the world . The difference is that today's pipe thread comes in many different Standards . The most common pipe threads in North America are designated as:

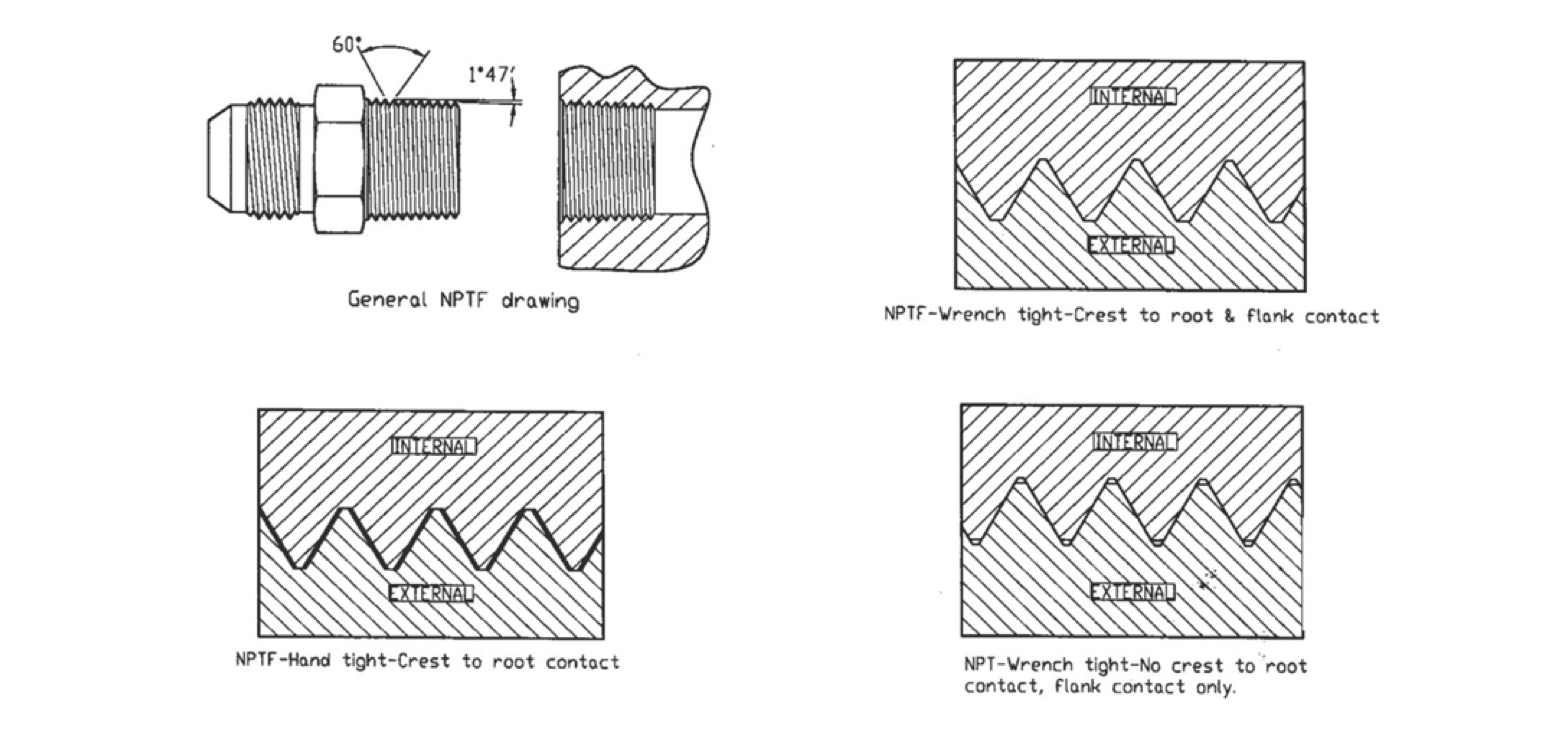

NPT = American (National ) Standard Pipe Taper NPTF = American (National) Standard Pipe Taper Fuel (Dryseal)

Due to variances in pipe thread engagement, the TURNS method of assembly is preferred over specific torque values.

Both NPT and NPTF taper pipe threads seal by deformation of the threads . NPT threads must be used with some form of pipe sealant due to the Crest-Root contact, or lack thereof, which leaves a spiral leak path even after assembly. The NPTF threads, however, are designed to seal without the use of any pipe sealant, hence the Dryseal designation. The Crest-Root contact is such that no spiral leak path is left, but pipe sealant is normally applied for added protection against leakage, galling, and to help evenly spread the assembly torque when tightening . Pipe threads should be tightened two full turns past finger tight on sizes up to 1 /2''. Larger sizes should be tightened 1 1/2 to 2 1/ 2 full turns past finger tight. To obtain a correct alignment for elbows and tees follow these instructions and then continue tightening to the desired point . Be careful NOT to accidentally back off or loosen a pipe thread to obtain correct alignment . It should be noted that a pipe thread is NOT recommended for vibration or temperature cycling environments . Pipe threads should also be limited to ONE use unless the system is low pressure. Since pipe sealant, tape or paste, is normally used and recommended , the proper method of installation is as follows:

To apply Sealant Tape, make sure the threads are clean. Then tightly wrap the tape in the clockwise direction from the lead end of the thread. Overlap half the width of the tape with each wrap applying no more than two plies per thread . Be sure to leave the first 1 / 2 to 1 1 / 2 threads bare to avoid system contamination or damage . Tape is recommended only if no sealant paste is used.

To apply Sealant Paste, make sure the threads are clean. (Sealant Paste can be found on page 11 ). Then evenly apply the paste over the threads , except for the first two , with care not to leave any air pockets or bubbles . Do not apply paste if sealant tape is already installed.

View Products: Pipe Adapters

See Products

Same Day Shipping

We guarantee same day shipping on all orders received before 4:00 p.m. CST for all in-stock products.

Home Page

Home Page