Hydraulic Flange Adapters– Technical Details

Hydraulic Headquarters offers Split Flange Adapters to convert Code 61 or Code 62 flange ports to JIC or OFS connections. Ranging in sizes from 1/2" up to 2'; these adapters are a convenient, cost effective way to replace expensive hose fittings. They not only make hose alignment easy, but once in place the hose assembly can be replaced with standard hose swivel ends. This eliminates the need for special part numbers and extra inventory. Hydraulic equipment can then be quickly interconnected while leaving the split flange O-ring connection unbroken.

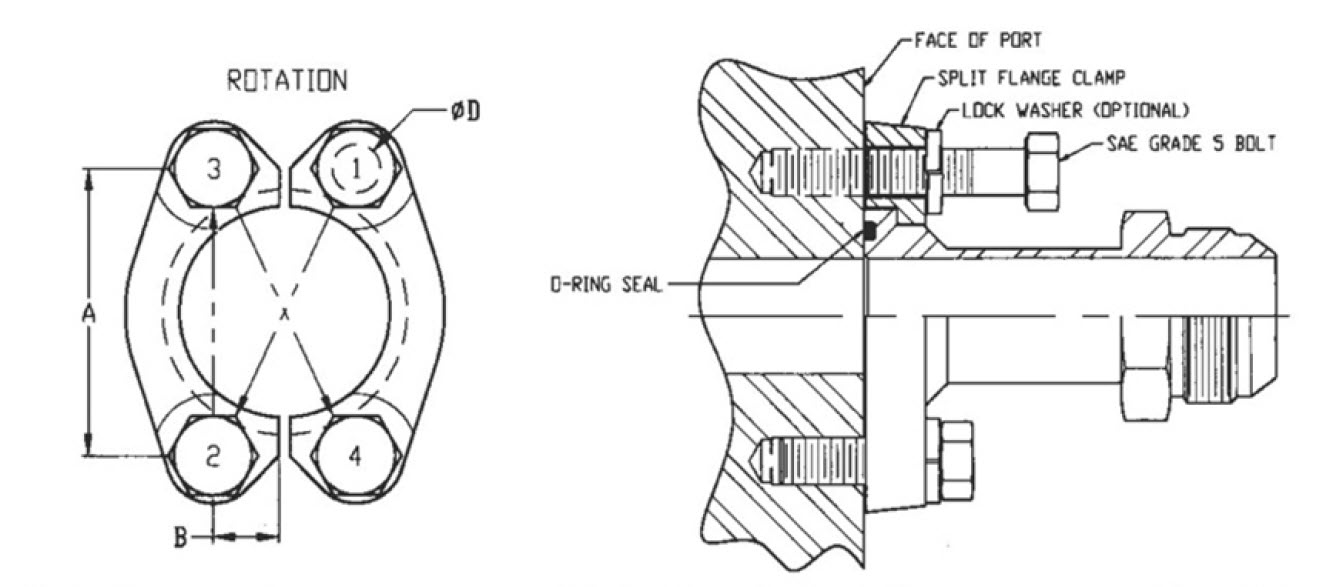

The 4-bolt flange design is used world-wide for connecting pumps and motors in hydraulic systems. The split flange halves work by clamping down on the port surface thereby compressing the O-ring into a metal groove in the flange head. The flange head makes a metal-to-metal contact with the port surface, so there is no place for the O-ring to extrude or deform under pressure. There are no spiral leak paths, sealing compounds, or gasket misalignments to contaminate the system or get in the way of a leak-free connection. The components that make up the Code 61 and Code 62 flange design are standardized by SAE under J518. Those components are the flange head adapter,a pair of 2-bolt split flange halves (clamps), four Grade 5 bolts and washers, and a 90 Durometer O-ring. The flange port design divides the load into four bolts, which require less torque than other port designs of comparable size. The flange head hose assembly can be removed quickly by pivoting one of the split flange halves out of the way. Simply remove one of the split flange bolts and loosen the others.

Assembly is easy. Standard bolts are used, so no special tools are needed. First make sure that the port surface and the flange head, including the O-ring groove, are free of nicks, dings, dirt, grit, or other foreign matter. Next lubricate the O-ring with 10W hydraulic oil and insert it into the groove of the flange head. Then insert the four bolts, with washers, through the bolt holes of the split flange halves and thread them in to the port finger tight. The flange head should be centered in-between. Partially tighten each bolt according to the rotation shown above until the specified torque values are obtained in the chart below. This method will reduce the chance of pinching the O-ring and/or over flexing the flange. It should be noted that the split flange halves never actually touch the port surface. A clearance of 0.010" to 0.030" should always be measured after the torque values are reached. Only the flange head makes a metal-to-metal contact. Code 61 and Code 62 have different bolt patterns and are not interchangeable. Other brands also have similar dimensions to the SAE J518 flange design, but they are not interchangeable either.

View Products: Hydraulic Flange Adapters

See Products

Same Day Shipping

We guarantee same day shipping on all orders received before 4:00 p.m. CST for all in-stock products.

Home Page

Home Page